How to motivate your employees through Kaizen in an FDA environment

Now, how can this be done? Although veterinary pharmaceutical manufacturer Parnell Manufacturing Pty Ltd adheres to stringent international quality standards, including the FDA, enthusiastic employees carry out countless Kaizens.

This article explores how Parnell has made a quantum leap in its continuous improvement journey with the implementation of Nebula, a system designed to manage employee suggestions and to drive continuous improvements.

Parnell: A Global Veterinary Pharmaceutical Company

Parnell is a multinational corporation specializing in veterinary pharmaceuticals. Established over fifty years ago, the company has a global reach, operating in fourteen countries. Parnell’s product range encompasses both companion animals and livestock, with a particular focus on reproductive performance and respiratory health solutions.

A significant component of Parnell’s operations is its manufacturing facility in Sydney, Australia.

This plant produces a range of sterile injectable products for veterinary use. It adheres to stringent international quality standards, including FDA, APVMA, ACVM, Health Canada, Saudi FDA, and EMA approvals and the Sydney facility is a cornerstone of Parnell’s global manufacturing network.

Working in a clean room at Parnell

Benjamin and Buddika drive Nebula forward at Parnell

At Parnell Manufacturing in Sydney Australia, the Nebula software system is the new tool that is used across the organization to process Kaizen suggestions and improvements.

I was privileged to be allowed to interview both Benjamin King and Buddika Liyanage about Parnell’s work with kaizen and with the implementation of Nebula.

Benjamin and Buddika work both at Parnell.

Benjamin is the Engineering Manager, and Benjamin has been at Parnell for nearly four years. He plays a key role in the company’s continuous improvement campaign. This campaign is a site-wide initiative championed by Leonardo Avendaño, the SVP of Manufacturing. Benjamin’s role is multifaceted. He oversees process engineering, maintenance and incoming projects. This year, Benjamin and his team have been leading many new initiatives. Nebula is at the forefront of these initiatives.

Benjamin works together with Buddika Liyanage on the Nebula project with Buddika as responsible for maintaining the manufacturing facility in Sydney.

Benjamin King and Buddika Liyanage – Parnell Manufacturing in Sydney Australia

The importance of company-wide participation in Kaizens

When asked about the main motivation for Kaizen at Parnell and for implementing Nebula Benjamin King explained, “It’s a combination of both employee motivation and increased focus on a Lean manufacturing culture. We are steadfast in our Lean initiatives and believe in Lean very strongly. Leaning up our processes is not just for profit, but also to be more agile as an organization,” he said.

He emphasized the company’s ability to adapt to market changes.

“One of our strengths is being a slightly smaller company in the pharmaceutical space, but with a decent market share. We can adapt to market changes and demands.”

Through continuous improvement and Kaizens, Parnell aims to streamline processes along the value stream.

“It’s less about profit and more about the success, adaptability, and agility of the company through Lean initiatives,” Benjamin noted.

He added, “We have a cost Kaizen category, but there’s no expectation to save a specific amount. It’s more about employee engagement and having a growth mindset. It’s not just the staff on the shop floor or the engineers thinking about improvements. It’s everybody, as a team, pulling in the same direction.“

FDA and Kaizen go well together with Nebula at Parnell

Parnell Manufacturing is all about continuous improvement. But it’s not always easy.

This is especially true when changes affect Standard Operating Procedures (SOPs). These are important for staying in line with FDA rules.

Benjamin says that Parnell has a special category for quality within their Kaizen system.

If a change is going to affect a SOP, it needs to be approved.

The manager or department head does this. They also think about, how the quality documents need to be changed. This is all part of the Kaizen. Most of their Kaizens are in this quality category.

Benjamin also says, “We let our employees find ways to improve the Quality Management System (QMS) through Nebula.” This system helps Parnell to make and put in place changes, including changes that need more steps, like making a Good Manufacturing Practice (GMP) form better.

Buddika, talks about Nebula: “The Kaizen System is part of Parnell’s Lean Daily Management System. We found Nebula and then made it fit our needs, and our Kaizen point system is one of the employees Key Performance Indicators (KPIs) at Parnell. A lot of people are involved in making and raising Kaizens. It’s a big part of their work. So, Parnell Manufacturing has found a way to keep improving while also following FDA rules. They use the Nebula system and their approach to Kaizen to do this.”

Kaizen Point System at Parnell Pharmaceuticals

Parnell Manufacturing has implemented a Kaizen point system to recognize the effort involved in employee suggestions.

Benjamin King explained that this structure was pioneered by their SVP of Manufacturing.

“Initially, we used to have just single-point Kaizens. You do a Kaizen, and you get one point. But over time we noticed that some Kaizens required a significant amount of work. This was especially true for Kaizens requiring significant quality SOP updates or change requests. A simple change on a machine may require many days of work because of the change requests, quality documentation updates and validations,” Benjamin added.

To acknowledge the level of work, they introduced a tiered point system.

“We have three tiers: single point, three points, and five points. Five points are reserved for major organizational changes or process changes with several contributors. It’s all decided on a matrix based on the effort and impact of the Kaizen,” he concluded.

Kaizen – the brainchild of the Parnell’s Senior Vice President

Before Nebula came into the picture, Parnell Manufacturing had a different approach to improvements.

Benjamin explains, “We’ve had the Kaizen system as it is today the last eight years. This system was the brainchild of Leonardo Avendaño the Senior Vice President (SVP) of Manufacturing, who still holds that position today. The old Kaizen system evolved over time, and the senior team introduced the idea of multiple contributors and introduced points and pre-approvals. However, the system had its limitations. The system was very paper-based, and the visibility of improvements was limited. Only the managers of the people doing the Kaizens could see the improvements across the facility. But strange enough, despite these limitations, there was a high level of employee engagement.”

Nebula was a Kaizen, and it improves the quality of the Kaizens

Benjamin says:” Before Nebula, Parnell Manufacturing had boards for Kaizens, but it wasn’t always up to date, and the teams worked a little bit more in silos. Each team, like Engineering, had their own Kaizen board. But these boards weren’t always current. The old system was based on paper. With many Kaizens each year, there were lots of papers.

Benjamin says, “You’ve got all these papers flying around everywhere. We had boards for the Kaizens. But it wasn’t used as much as would hope.”

Benjamin explains, “We had a board, but it wasn’t heavily upheld.” So, before Nebula, the teams at Parnell were working separately. They were making improvements, but it wasn’t as organized as it is now with Nebula, and we had less visibility and less collaboration. The decision to introduce Nebula at Parnell Manufacturing was therefore a strategic one.”

Buddika Liyanage, the Maintenance Engineer, explains, “Nebula is now part of our Kaizen system. We raised Nebula as a Kaizen, the management approved it, and they started to implement it. One of the key reasons for introducing Nebula was the visibility that helps to improve the quality of the Kaizens. If I’m raising my Kaizen, everyone can see my Kaizen. This visibility encourages employees to think about the quality of their Kaizens”.

Benjamin King agrees, and he says, “The big motivator to take this on was the administration functions, the visibility that Buddika was talking about. Before Nebula, we had a paper-based system for eight years. It was fairly clunky, and introducing Nebula was felt like a natural progression.”

Benjamin shares, “When Buddika tabled the idea with the Nebula guys, we were all pretty keen to give it a go. And it worked out well. So, Nebula was introduced at Parnell to improve the Kaizen system and make it more visible and efficient.”

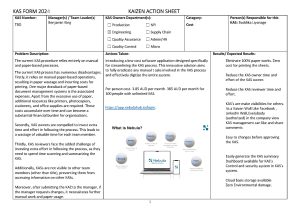

Excerpt of Kaizen form from when Buddika Liyanage proposed Nebula as Parnell’s new electronic Kaizen system, for collecting and managing improvement initiative

The Roll-out of Nebula at Parnell

Buddika played a crucial role in implementing the Nebula system.

“Buddika gave a brilliant presentation,” Benjamin recalled.

“The initial phase involved customizing the Kaizen system to match Parnell’s existing Kaizen system. We had several meetings with all the team leaders and managers. We communicated via email and held a couple of presentations to introduce the system. To facilitate adoption, employees received manuals and login details followed by a testing period. We got really positive feedback, especially from the team leaders and managers. The rollout strategy began with training managers and team leaders due to their in-depth Kaizen system knowledge. Subsequently, the system was extended to all employees. Employee acceptance of Nebula has been overwhelmingly positive. We received really good feedback. There was no resistance because it’s very easy to use compared to the manual system. You just need to log in and add your suggestion. This simplicity has been a key factor in the Kaizen system’s success.”

Both Buddika and Benjamin emphasized the positive feedback from employees and managers.

“People have come to me saying the team is really well receiving this,” Buddika concluded.

Benjamin corroborated this sentiment, stating, “I’ve had managers coming directly to me with feedback on how much they appreciate and enjoy the Nebula system. The absence of negative feedback is a strong indicator of the system’s effectiveness. I don’t think I’ve heard a single person say they’re struggling with the system, or they don’t like it.”

“I think everyone’s on board,” Benjamin concluded.

370 Kaizens in two months with Nebula

Nebula is embraced by all employees within the manufacturing facility, from managers and team leaders to senior VPs, operators, and engineers.

As Buddika, explains, “Nebula is a tool for everyone within the manufacturing facility.”

But the use of Nebula extends beyond the manufacturing floor.

As Benjamin points out, the system is driven by the SVP of Manufacturing and the executive leadership team. It’s not just about continuous improvement on the shop floor, which is undoubtedly the heart and soul of the business. Nebula is also applied to the administration team, facilitating improvements in administrative and transactional processes.

When asked about the number of improvements in the system, Buddika provided some figures. “You can see in the system that we have had around 370 Kaizens in two months,, and in about eight years, we’ve had nearly 4,000 Kaizens.”

And Benjamin emphasized that Nebula is more than just software. “It’s the whole package the guys offer that has been tremendous,” he said.

The system is tailored to Parnell’s needs, and the support from the Nebula team is excellent. “They take our requests and jump on them straight away. They’re there every single day to support us.”

He contrasted Nebula with off-the-shelf solutions. “For us, it’s a whole package tailored exactly for our organization’s requirements and demands,” he explained.

The support has been crucial. “The support and guidance they provide is the other business value add that the Nebula guys bring. I couldn’t fault it,” Benjamin concluded.

Parnell employees even use their own cell phones for Kaizen

Kaizen proposals are created both on computers, laptops and even on the employees’ own cellphones at Parnell.

According to Benjamin King, Nebula is accessible on desktops, laptops, and tablets provided by the company.

While employees can use their own cell phones, most engagements occur on computers due to the clean room environment.

Benjamin explains, “Typically what we see, most of the engagements are on computers. Being a clean room, the operators won’t take their cell phones into the production facility, but they have dedicated laptops and computers down there. However, some employees use their own cell phones when they are outside the higher-grade clean rooms. This is because Kaizen suggestions are a crucial part of their KPIs. Having access to Nebula on their own phones allows them to quickly and conveniently make suggestions. So, we use both platforms. Ensuring that all employees have access to Nebula is essential for our Kaizen suggestion system. It’s important that everyone has access and it’s not restrictive in any way,” emphasizes Benjamin.

Working with the Nebula Kaizen system om a computer at Parnell

Working with the Nebula Kaizen system om a tablet at Parnell

The Kaizen flow within Nebula at Parnell

When asked about the practical Kaizen flow using Nebula, Benjamin explained, “Typically, the direct manager decides if an employee can spend time on an improvement. Kaizens go for pre-approval to the direct manager. If it’s a big three or five-pointer Kaizen involving significant resources, they also go to the senior team for pre-approval. This ensures it’s worthwhile for the time spent. Very rarely does anything get knocked back. Sometimes, a manager might suggest adding more people to a Kaizen for support. This way, multiple people can gain points, making it a collaborative approach. And Nebula acts as both a task manager and a system to document improvements. When employees put an idea into the system, they describe the present state, take a picture, and propose the after state with another picture or with a diagram. They outline the steps to achieve the improvement, and the work involved. Once the idea is formed, it is sent for pre-approval. It’s both a task manager system and a system to show what we’ve done.”

Kaizen Rewards for employees at Parnell Manufacturing

Benjamin explained the reward system: “We have an annual awards night, where the best Kaizens are recognized on stage and receive a reward. It’s one of the most enjoyable parts of the night. Overachieving in continuous improvement is also reflected in an employee’s KPI performance, leading to further incentives. It’s only the very best of the year that get rewarded, creating a healthy competition. Employees can see each other’s points in the Nebula system. They can see who the top 10-point earners are, which creates a bit of competition,”

Buddika Liyanage said, “ We have a separate page for each user to help motivate them. Sharing ideas is also encouraged. If I raise a Kaizen, I can put another person in as a contributor, and when it’s approved, both get a mark. This builds teamwork. Visibility of Kaizens also inspires collaboration. We can see other people’s Kaizens, which can inspire us to implement similar ideas. People can like and comment on Kaizens, increasing motivation.

And Buddika added, “ This improves collaboration.”

Does Nebula implementation always need a top-down approach?

“I think the Nebula product and service could be implemented in a small team wishing to get started with their continuous improvement journey, whether it’s a production team or site-wide,” Benjamin explained.

He highlighted that support and commitment from the top can significantly enhance the implementation process. “When you have support and commitment from the very top, it’s incredibly beneficial.

It’s not essential, but it’s a great way to ensure the system is implemented and supported. You’re all on the journey together.” However, Benjamin also noted that Nebula’s solution is versatile and can fit various use cases.

“You could take the Nebula solution if a production manager was just looking to implement it for their team and get the ball rolling. It can fit every sort of use case,” Benjamin added.

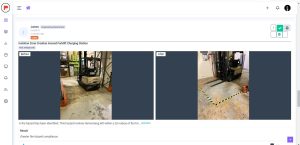

Before and after Kaizen at Parnell – shown in Nebula at Parnell

The Nebula Smart Kaizen Platform is a cutting-edge digital lean system designed to improve how organizations manage Lean projects and kaizen initiatives. Developed by a team with the backing of the Center for Lean Excellence Pte. Ltd., Nebula simplifies complex lean processes by digitizing and automating tasks, enabling organizations to eliminate waste and achieve greater efficiency. The platform provides real-time visibility into project progress, robust analytics for tracking financial and operational improvements, and seamless collaboration tools, ensuring continuous employee engagement and accountability. Nebula addresses common challenges in Lean administration, such as the reliance on paperwork, spreadsheets, and manual tracking, by offering a single system that integrates all aspects of Lean project management. This results in time savings, enhanced communication, and improved decision-making. With a team of experts, Nebula is supported by a workforce passionate about advancing digital lean applications and driving impactful transformations for businesses.